hey whats up everybody. haven't been around to much since nalm 08. been pretty busy with other things. i started working back on the car though so i thought i would share my progress thus far.

got the engine pulled several months back

this is how u remove the exhaust with rounded bolt heads...with a fuckin sawzall. i would only suggest this if u r replacing with obx headers as i am though lol

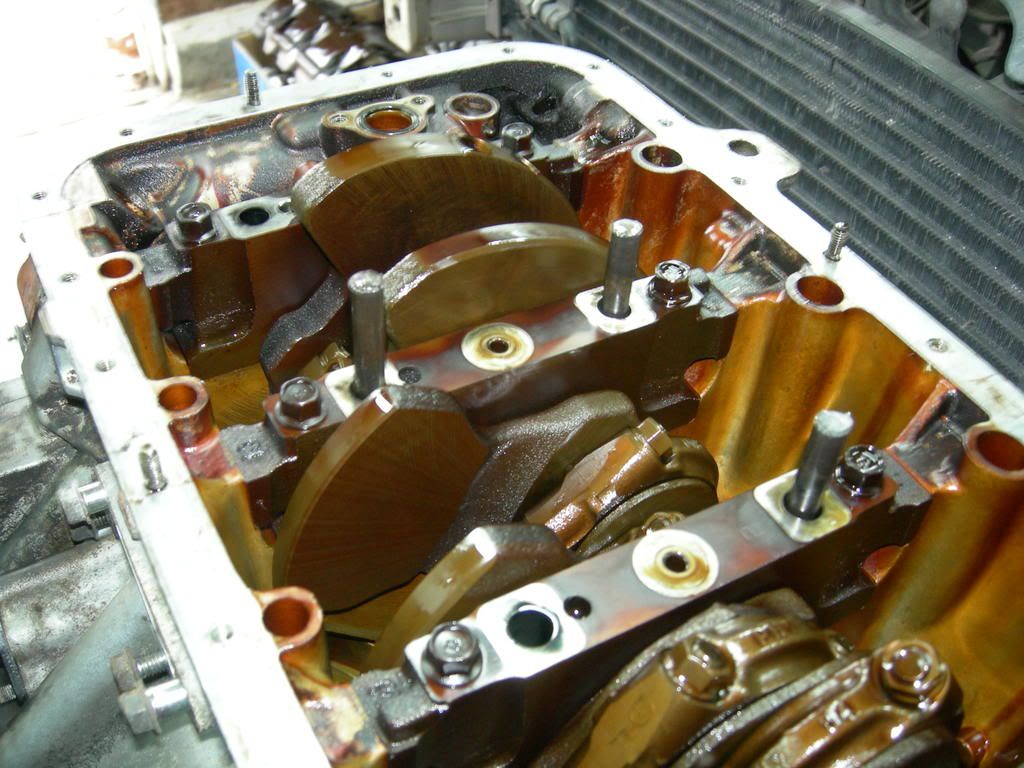

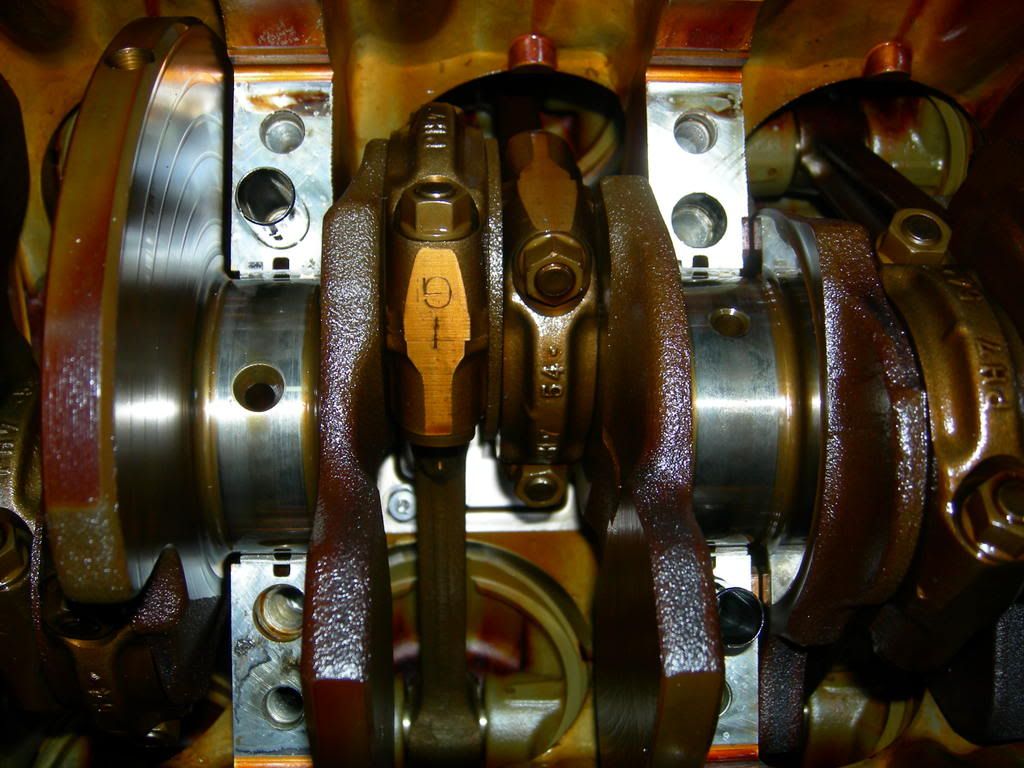

started pulling apart the engine last week for rebuild.

covers prepped for paint

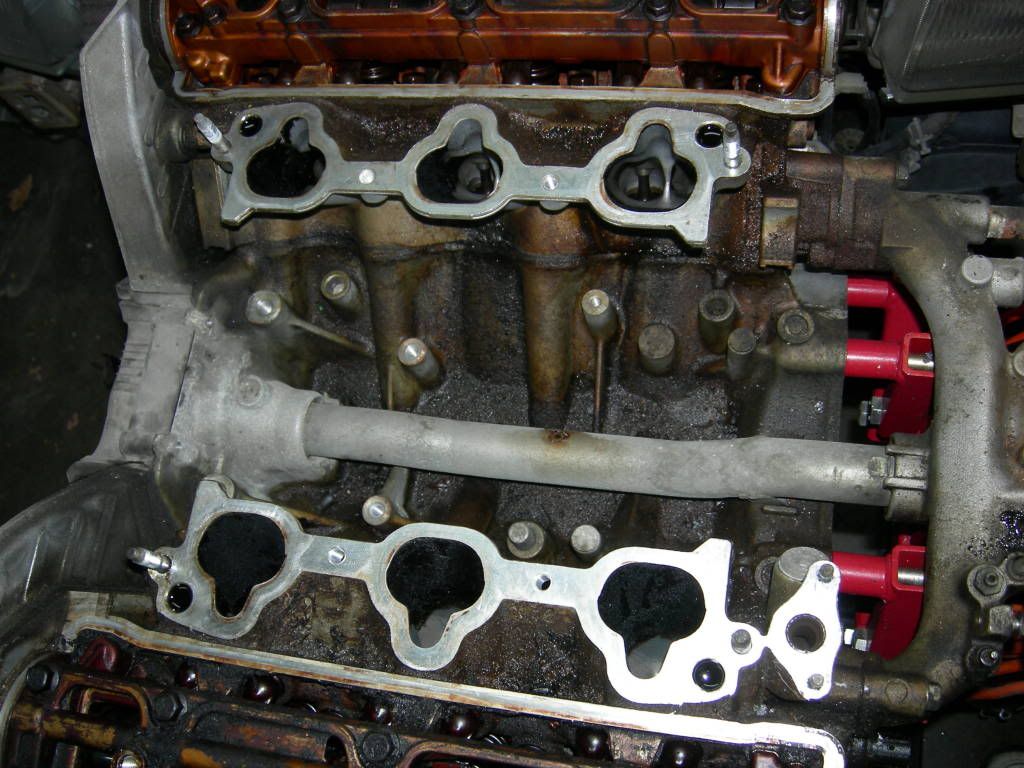

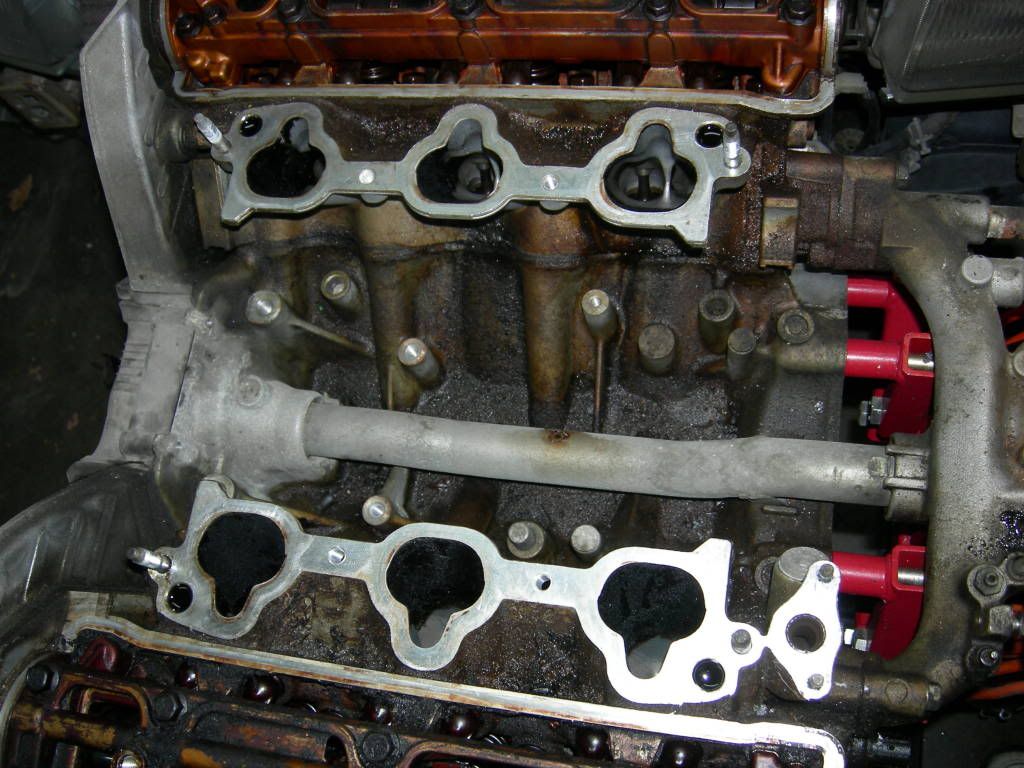

intake manifold removed

also this may be a good note to most of u out there with cars of this age. hoses i never would have thought to check for replacement. these hoses look terrible. not to mention the rusted out water pipes they connect to. i don't know if it was the coolant used or what.

lots of cleaning to do.

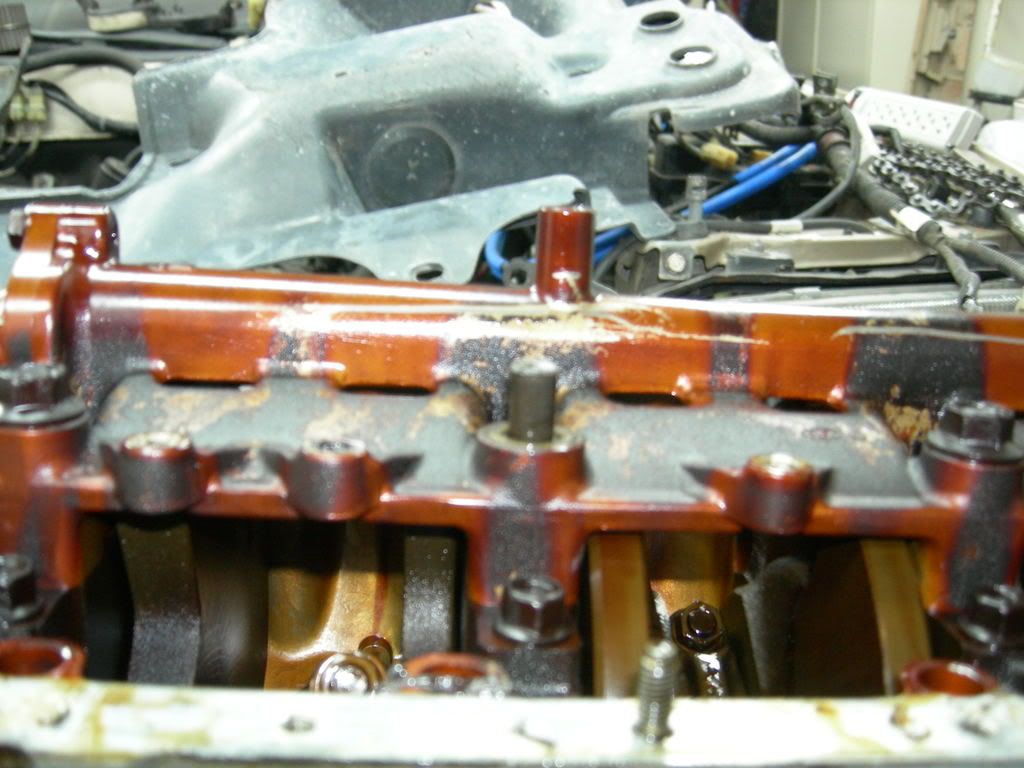

and this is what carbon buildup looks like under your valve covers. use seafoam kids!!!!!!

got the engine pulled several months back

this is how u remove the exhaust with rounded bolt heads...with a fuckin sawzall. i would only suggest this if u r replacing with obx headers as i am though lol

started pulling apart the engine last week for rebuild.

covers prepped for paint

intake manifold removed

also this may be a good note to most of u out there with cars of this age. hoses i never would have thought to check for replacement. these hoses look terrible. not to mention the rusted out water pipes they connect to. i don't know if it was the coolant used or what.

lots of cleaning to do.

and this is what carbon buildup looks like under your valve covers. use seafoam kids!!!!!!