First I apologize for the serious teaser and putting up pics of a project without results and dyno's because there are none. And who knows how long it could be before I go any further it could be a year or more! I just love hearing the ideas suggestions, feedback and knowlege you all have to offer. Isn't that a bulk of what we are here for?  Well as many of you know I am currently underway with the Supercharger setup. It has been a very slow process but is still underway and the manifold for it is now being welded from what I understand.

Well as many of you know I am currently underway with the Supercharger setup. It has been a very slow process but is still underway and the manifold for it is now being welded from what I understand.

I could not get over how much I loved Hotlava's tt setup and it overcame me. So I figured at some point in the future I also wanted to do a tt setup and began slowly buying the additional pieces it would take to do so (being that many are the same, such as injectors, fuel pump monitoring gauges and what not). Then last week my car decide to get some garage time (it broke down later found to be a broken axle, Ebay? I think it was tsk tsk). But none the less it was a perfect excuse to play while she was down so I started to look at how I would eventually want my tt to be setup. What better way than to play. It helps kill concepts that look good in your head given the (not so) workable space; a few of my ideas have since died. But long story short this is where I am at so far. Now that my wife knows that it is just a broken axle I only have shipping time to continue playing before having to put her back together again.

A couple quick notes

-No this will not be done/completed for a very very long time.-This is very new to me so I would be the last to ask for suggestions though I love to share ideas.

-Yes the supercharger project is still underway and taking precedence over this.

-No I did not wake up one morning and say I am going to do a Legend Twin turbo setup during breakfast (sorry Hybird, that just kills me lol)

-No I am not going to be using PVC intercooler piping it is just cheaper to hack away at till I figure how I am going to do it when the time comes.

-I have also read up on some articles of Twin vs. Single and each seem to have there advantages from knowlegable members of their respective forums.

-cheap clamps will be replaced with t-clamps.

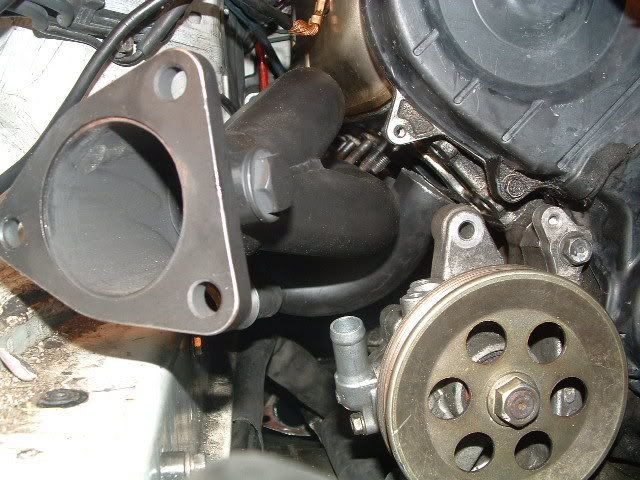

Ok the book is done here's the pics. (excuse the mess my garage is at war)

also please forgive the ugly "stand in" mesh and terrible paint, looks will come last. I don't want to tear it up after doing body work and paint.

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

This one concerns me, there is not much rook and there is a damn brake fluid line that may need to be relocated. wires and hoses I don't mind moving brake, AC, and power steering lines I am not so happy/experinced with.

![Image]()

Hopefully at some point I will be done destroying my car and be able to build it up like the one in my head lol.

-Tip- If you get a new intercooler or radiator, cover the fins with cardboard until it is fully installed so you don't damage the fins during installation :hide:

PS. The purple finish and and nice shiney engine bay will be back in time. it was too hard to maintain and not scratch to hell while getting a bug of some sort and doing stuff like ^ this. I think eventually I will powdercoat vs. paint though.

I could not get over how much I loved Hotlava's tt setup and it overcame me. So I figured at some point in the future I also wanted to do a tt setup and began slowly buying the additional pieces it would take to do so (being that many are the same, such as injectors, fuel pump monitoring gauges and what not). Then last week my car decide to get some garage time (it broke down later found to be a broken axle, Ebay? I think it was tsk tsk). But none the less it was a perfect excuse to play while she was down so I started to look at how I would eventually want my tt to be setup. What better way than to play. It helps kill concepts that look good in your head given the (not so) workable space; a few of my ideas have since died. But long story short this is where I am at so far. Now that my wife knows that it is just a broken axle I only have shipping time to continue playing before having to put her back together again.

A couple quick notes

-No this will not be done/completed for a very very long time.-This is very new to me so I would be the last to ask for suggestions though I love to share ideas.

-Yes the supercharger project is still underway and taking precedence over this.

-No I did not wake up one morning and say I am going to do a Legend Twin turbo setup during breakfast (sorry Hybird, that just kills me lol)

-No I am not going to be using PVC intercooler piping it is just cheaper to hack away at till I figure how I am going to do it when the time comes.

-I have also read up on some articles of Twin vs. Single and each seem to have there advantages from knowlegable members of their respective forums.

-cheap clamps will be replaced with t-clamps.

Ok the book is done here's the pics. (excuse the mess my garage is at war)

also please forgive the ugly "stand in" mesh and terrible paint, looks will come last. I don't want to tear it up after doing body work and paint.

This one concerns me, there is not much rook and there is a damn brake fluid line that may need to be relocated. wires and hoses I don't mind moving brake, AC, and power steering lines I am not so happy/experinced with.

Hopefully at some point I will be done destroying my car and be able to build it up like the one in my head lol.

-Tip- If you get a new intercooler or radiator, cover the fins with cardboard until it is fully installed so you don't damage the fins during installation :hide:

PS. The purple finish and and nice shiney engine bay will be back in time. it was too hard to maintain and not scratch to hell while getting a bug of some sort and doing stuff like ^ this. I think eventually I will powdercoat vs. paint though.